Jena / August 12, 2024

3D measurement with no risk

3D-Vens project develops endoscopic sensing unit to enable 3D imaging in explosive atmospheres

The project 3D-Vens, i.e. “3D measurement using explosion-proof endoscopy with structured illumination”, aims to develop an endoscopic sensor free of any electronic component for use in highly sensitive environments – such as hydrogen tanks and pipelines. The project is funded by the Federal Ministry of Education and Research with about three million euros over the next three years.

Hydrogen is envisaged to be an important energy carrier of the future and could play a key role on our society’s and our economy’s road to climate neutrality. The safe and efficient maintenance of hydrogen infrastructure is essential to transfer systems into application. Surface inspection inside tanks and pipelines at industrial scales typically relies on commercial endoscopes which image the inside of objects in 2D or 3D.

However, hydrogen is a highly flammable gas, a highly explosive mixture when combined with air. Hence, the operation of conventional endoscopes poses a serious risk in such environment. A team consisting of three commercial enterprises as well as researchers and engineers from the Friedrich-Schiller-University Jena and the Fraunhofer Institute of Applied Optics and Precision Engineering IOF aims to expand the domain of endoscopic sensing to such sensitive environments.

Safe measurement of hydrogen tanks

In the project 3D-Vens, i.e. “3D measurement using explosion-proof endoscopy with structured illumination”, the partners are going to develop an explosion-protected sensor system for 3D measurement that does not require any active electronic component inside the endoscopic sensor head, that is the device directly operated in a hydrogen environment.

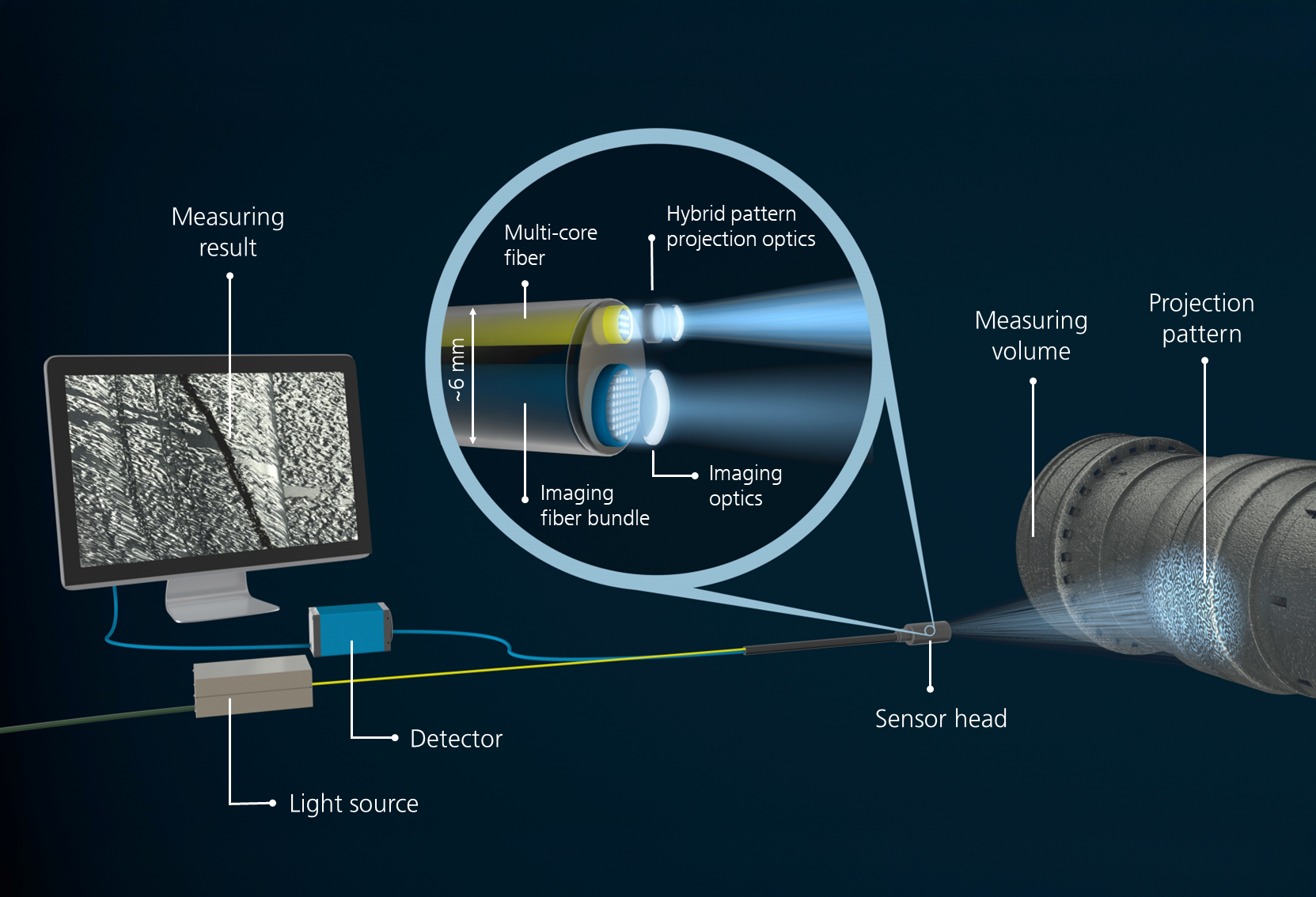

Until now, conventional endoscopes require two cameras and at least one additional illumination channel for pattern generation to finally reconstruct a 3D image. On the contrary, the concept pursued within 3D-Vens just relies on a single imager and a single pattern generator. Most importantly, the light is entirely guided within optical fibers and fiber bundles such that light sources and image sensors can be decoupled from the explosive environment.

New measuring system without electronic components

The optical system to be developed uses light and multi-core fibers – bundles of up to 24 individual single mode fibers – to feed the pattern generation optics. Therefore, a customized micro-optical projection system generates structured illumination to create a stable and repeatable pattern. The light reflected from the test specimen is captured by miniature optics and guided into an imaging fiber bundle, which transmits the light pattern to a detector, e.g. a camera, outside the hydrogen tank. This allows details in the order of 100 micrometers to be resolved in 3D and in real time.

Fraunhofer IOF contributes with its expertise in the fields of optical and mechanical system design, with its strong background in modelling and design of diffractive and refractive micro-optical components. The researchers are also in charge of the design and manufacturing of customized optical multi-core fibers. Eventually, IOF’s contribution also includes integration, assembly, and test activities in close cooperation with all other project partners.

Opening up new maintenance scenarios

Thanks to explosion-protected endoscopy, new measurement volumes can be accessed in the future. The new method could therefore be used in a range of risky scenarios. Alternative possible applications include sensing under difficult conditions such as high pressure or extreme temperatures. The technology presented is more robust against cable deformation in the endoscope and significantly smaller than previous systems. This opens up new areas of application, e.g. for pattern projection, 3D measurement of special pipes or translational endo-microscopy for industry and medicine.

Partners in the project

3D-Vens is coordinated by ITConcepts GmbH and the Institute of Applied Optics and Biophysics at Friedrich-Schiller-University Jena. In addition to Fraunhofer IOF, the companies GRINTECH GmbH and INGENERIC GmbH are also involved in the project. It is being funded by the Federal Ministry of Education and Research with almost three million euros until 2027.