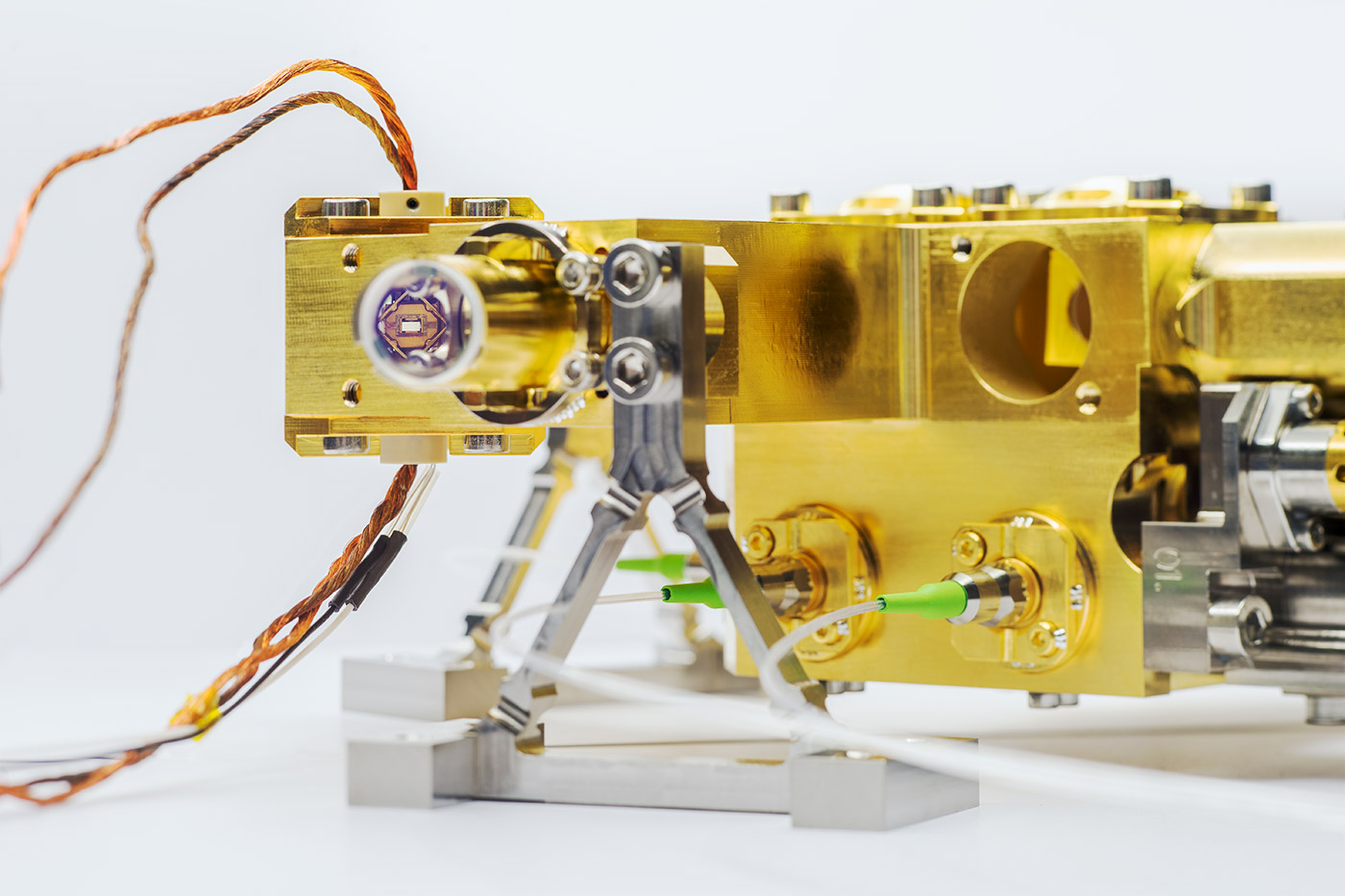

The "Fluorescence Imaging Spectrometer" (FLORIS) will be the centerpiece of ESA's "FLuorescence Explorer Mission" (FLEX). For the spectrometer, the IOF manufactured an assembly whose requirements were at the limits of what was technically possible. The high-precision double slit was realized with a slit width of exactly micrometers over a length of 44.15 millimeters. Both slits are assembled highly parallel to each other and possess a slit planarity of less than 10 micrometers. A roughness requirement of 0.3 nanometers rms (root mean square) was accomplished for the mirrors that are intended to guide the light onto the detector inside the spectrometer.

The double slit was manufactured on a silicon basis. A special lithographic process chain was developed at Fraunhofer IOF for production, in which lithographic structuring techniques were adapted for etching silicon wafers. Finally, the slits were given a black coating in order to achieve the specified optical reflectivity and optical density.

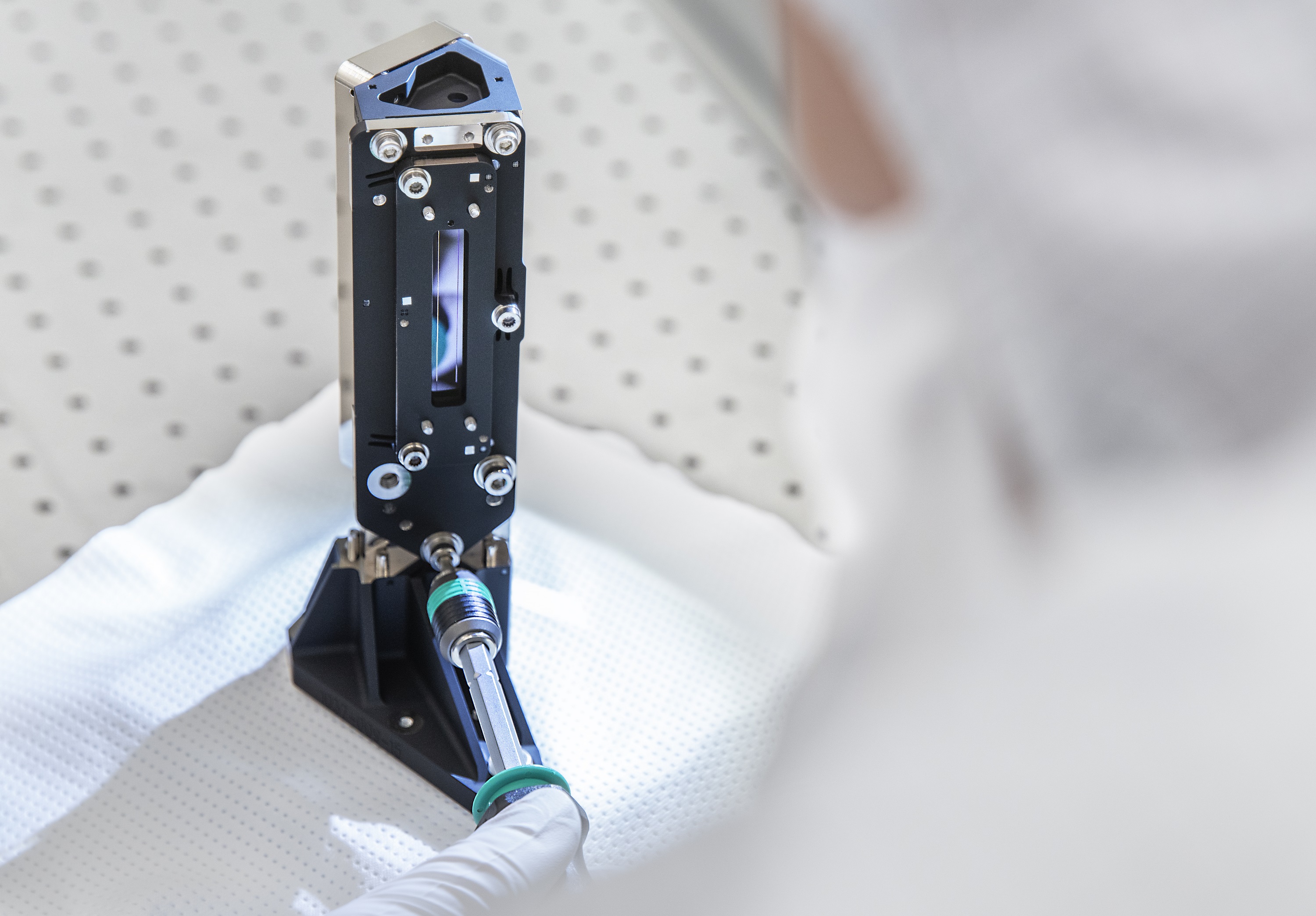

The device is designed so that the silicon double slit is mounted in a mechanical holder, which makes the assembly so robust that it can withstand the severe conditions at the launch of the FLEX satellite undamaged. A special assembly concept was developed from a combination of positive locking, clamping, and bonding, to realize this.