While the EUV lithography at 13.5 nm is close to market launch, the basic concepts for the next generation with a working wavelength of 6.7 nm must be investigated now. Here, high reflective multilayer mirrors (R ≥ 70 %) act as a key technology and have been developed by Fraunhofer IOF over the last three years.

Consisting of more than 500 alternating layers of Boron and Lanthanum compounds, each with a thickness of only a few nanometers, these mirrors may reach up to 80 % reflection in theory. However, due to imperfect film growth and interdiffusion at the interfaces, such high optical performance cannot be achieved in real multilayer structures.

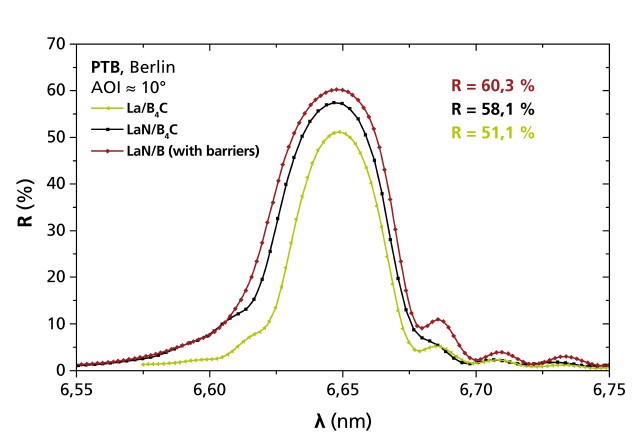

Through the choice of suitable and chemically more stable materials, high reflectivities of 58 % could be reached. In addition, ultrathin diffusion barriers with only a few Ångström thickness (d ≤ 0,5 nm) can be applied at the interfaces, increasing the reflectance to more than 60 %.

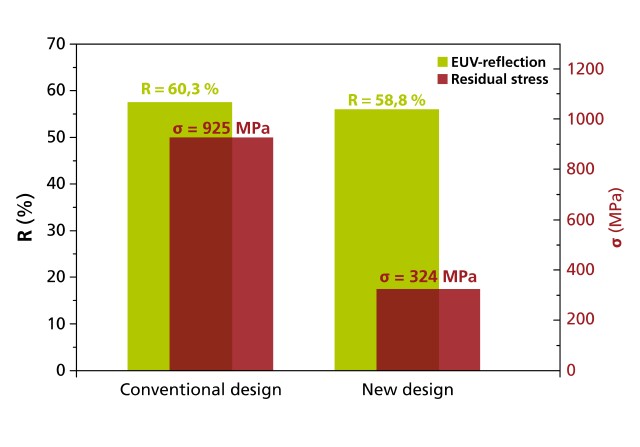

In addition to high reflectivity, industry demands low-stress coatings capable of withstanding elevated temperatures of up to 200 °C. After annealing up to 250 °C, LaN/B4C multilayer showed slight reflection losses of only 3 %. Even after tempering at 800 °C for 10 h, a periodical structure of the multilayer still existed, thus verifying the sufficient thermal stability. The high residual stress of about 1 GPa could be significantly reduced to one third of the initial value by the introduction of compensating layers into the multilayer design while still maintaining high reflectivity.

Nonetheless the research on the multilayer mirrors is still ongoing. Although Fraunhofer IOF has developed three patents for high reflective and low-stress multilayer mirrors for 6,x nm, even higher reflectivities and more stable coatings have to be developed by the market launch within the next 10 years. Meanwhile, other institutes such as Fraunhofer ILT in Aachen are pushing forward the research for powerful light sources.

Authors: Philipp Naujok, Sergiy Yulin, Norbert Kaiser