Construction and connection technology for and with optical glass fibers

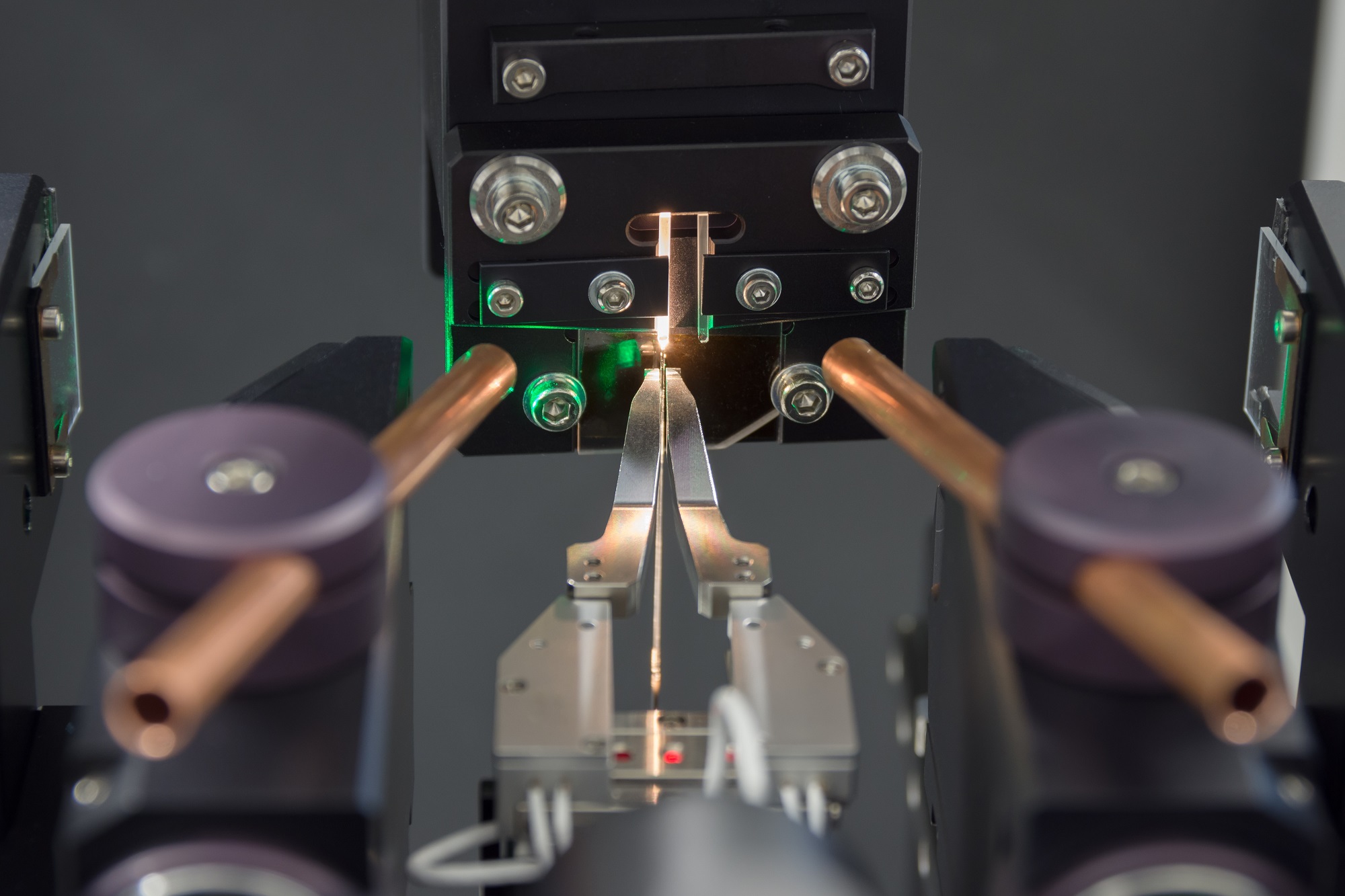

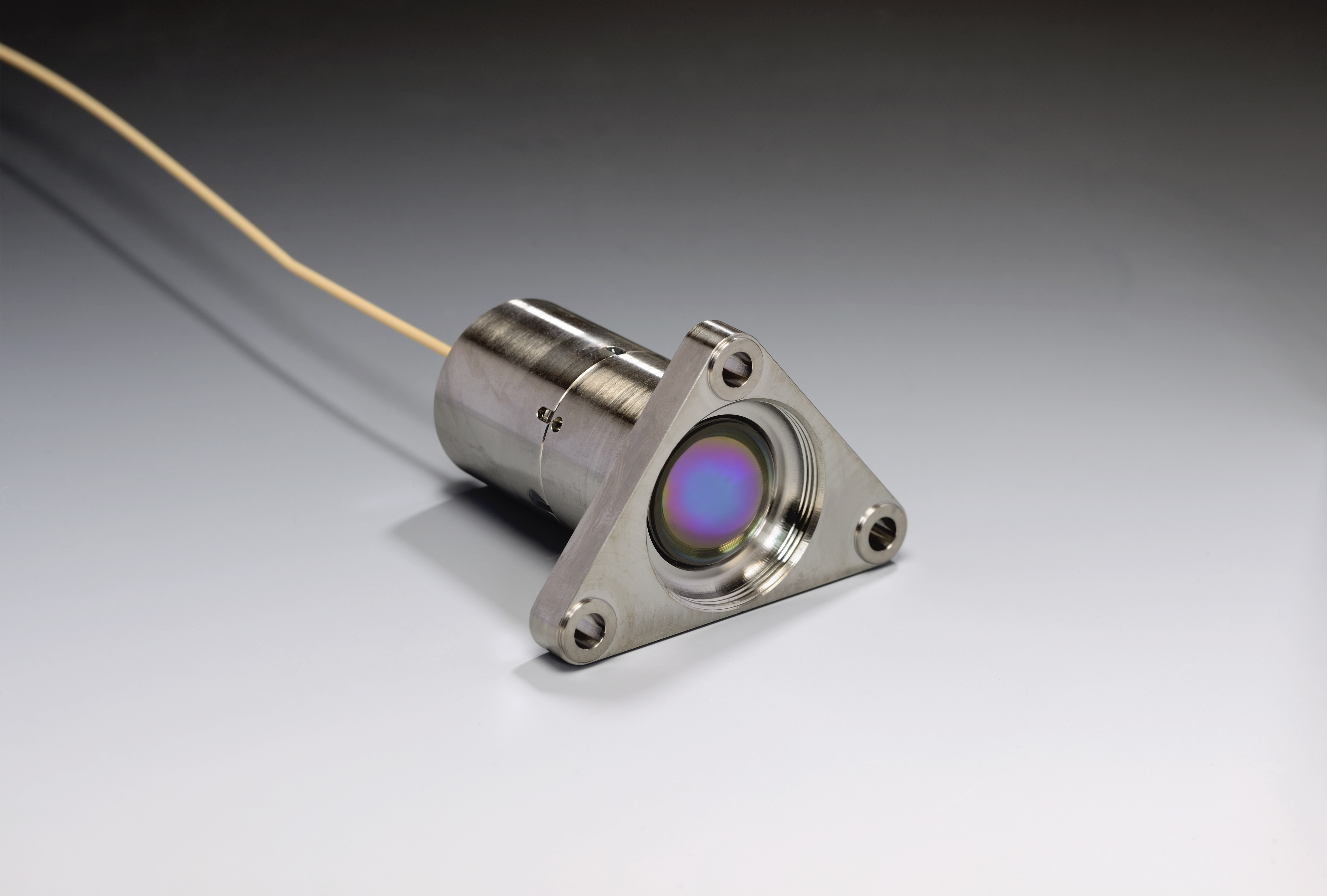

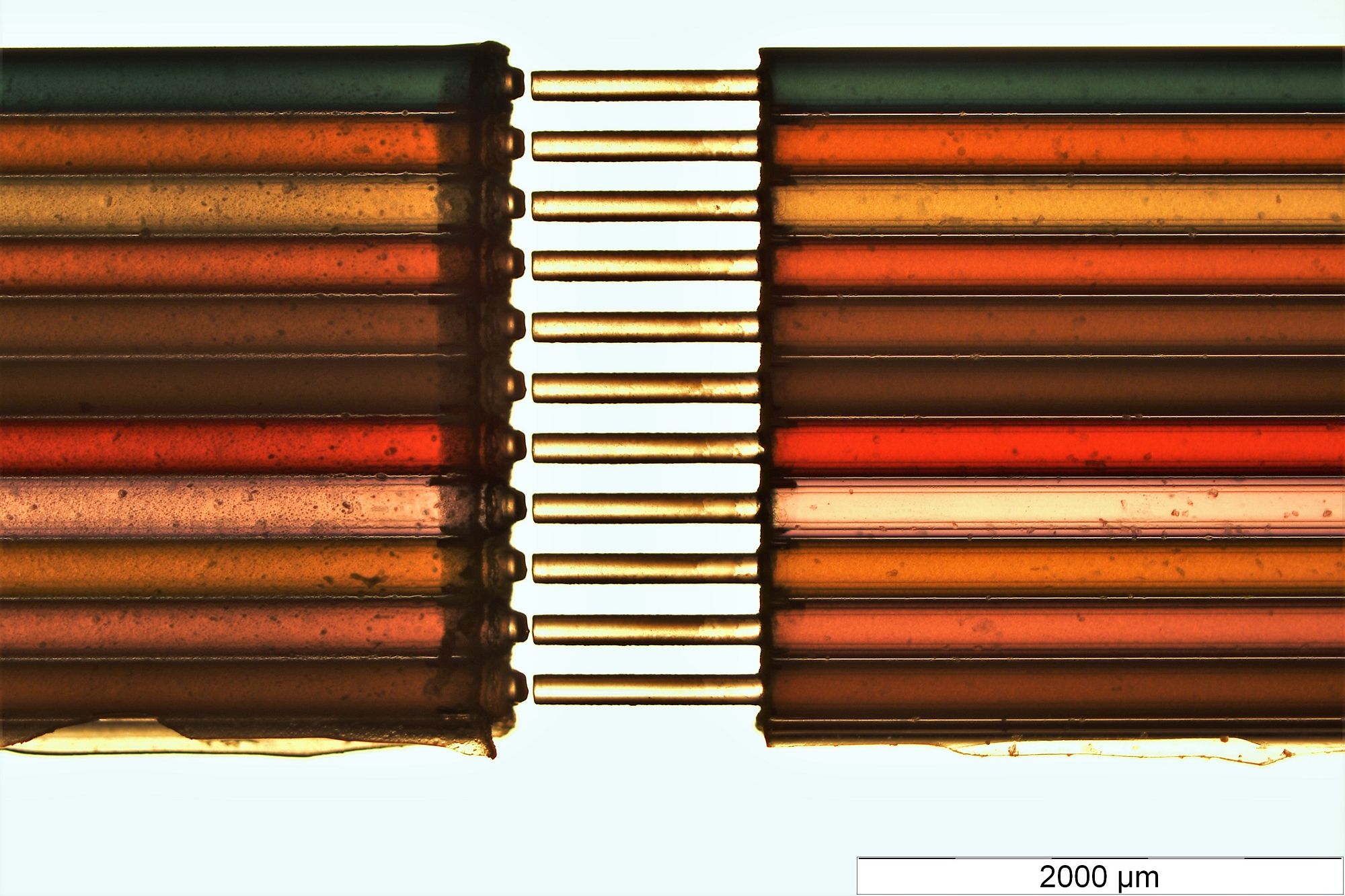

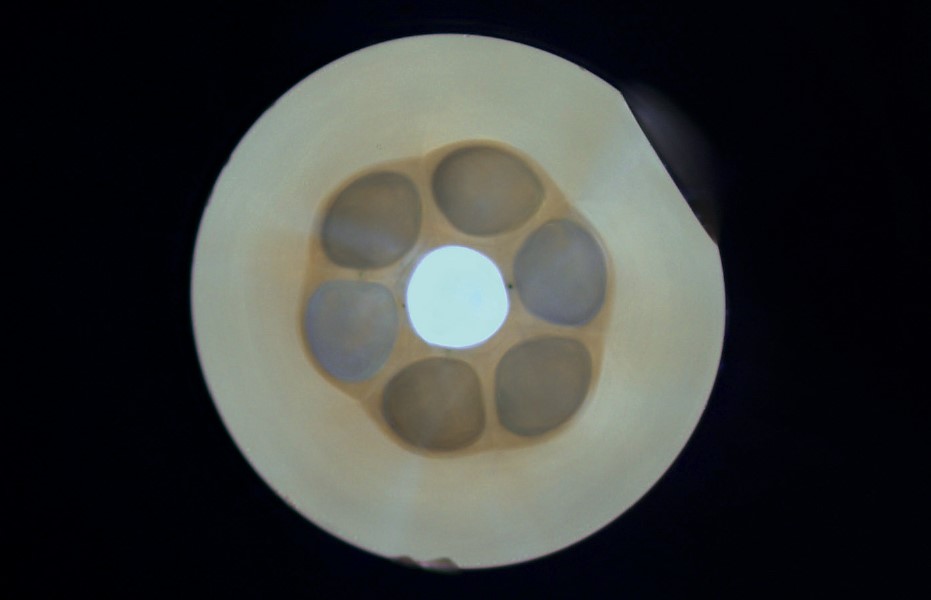

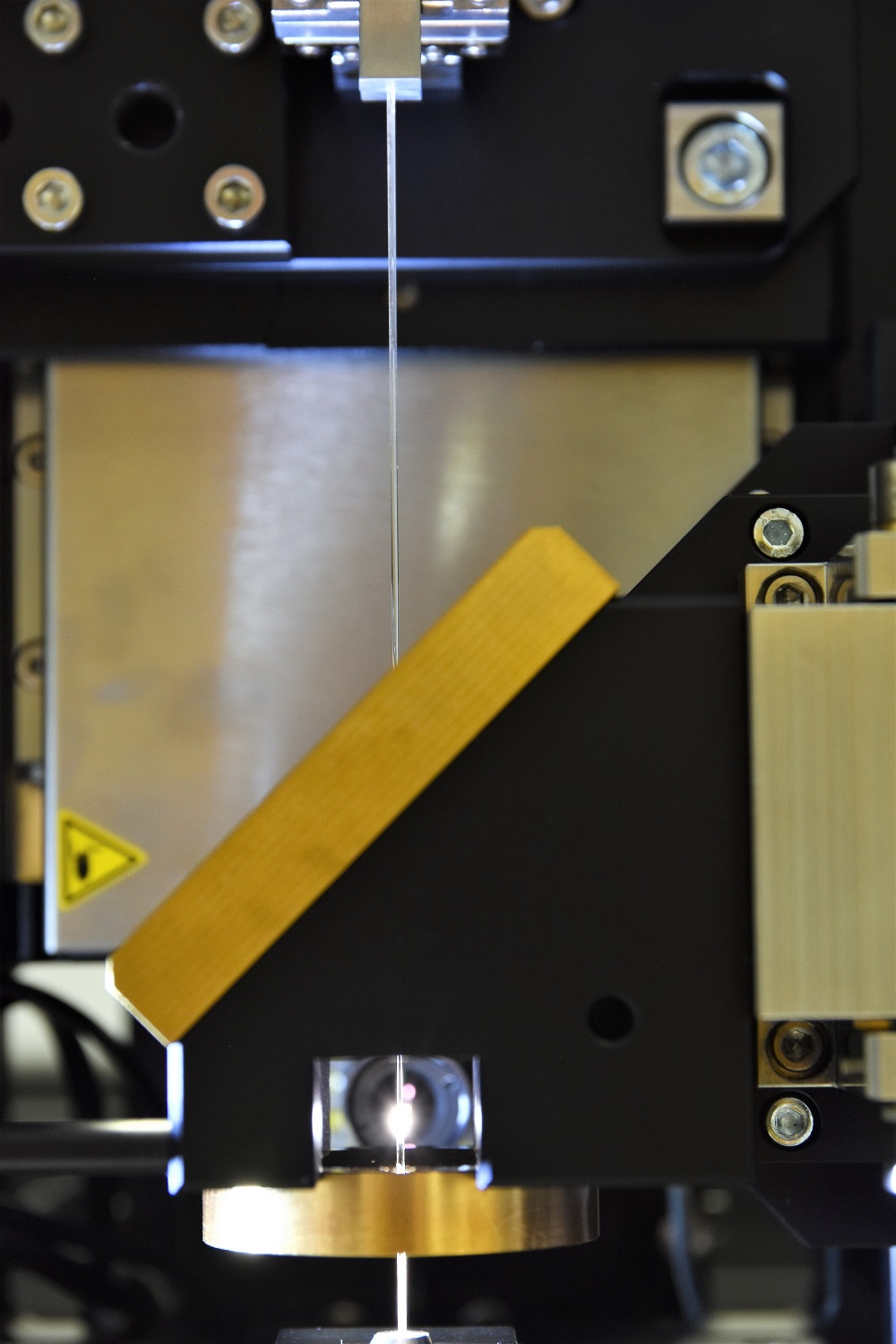

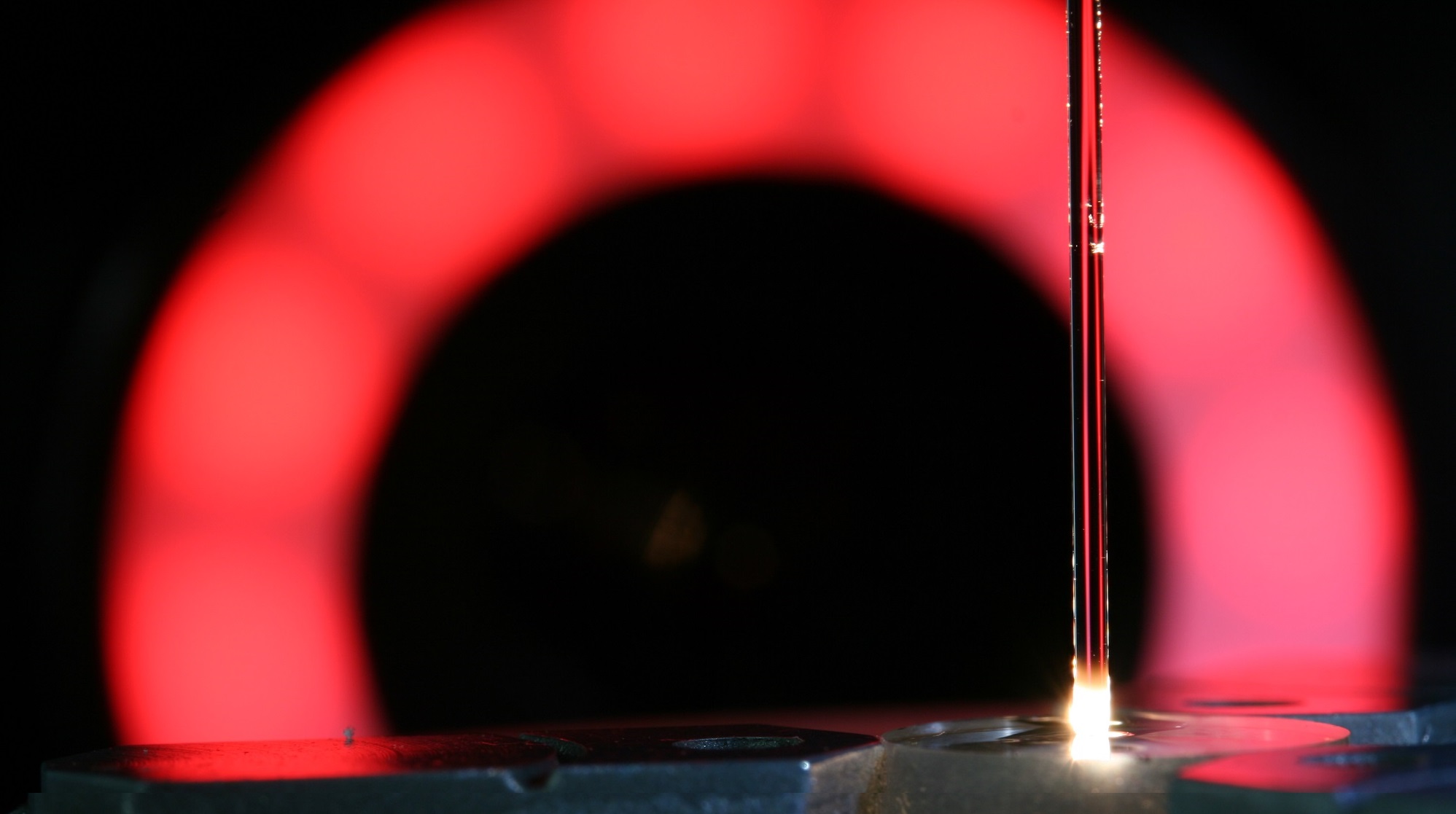

Low-loss signal transmission with high bandwidth via glass fibers is one of the major drivers of innovation in today’s information and communication society. If higher laser performances up to the kW range are to be transmitted by glass fibers, conventional assembly and joining technologies can oftentimes be used only to a very limited extent. The application of an appropriate CO2 laser as a contamination-free energy source for precise and flexible glass fiber processing is the ideal condition for a variety of innovative glass processes.