Additive manufacturing of micro- and macro-optics and individualized functional integration

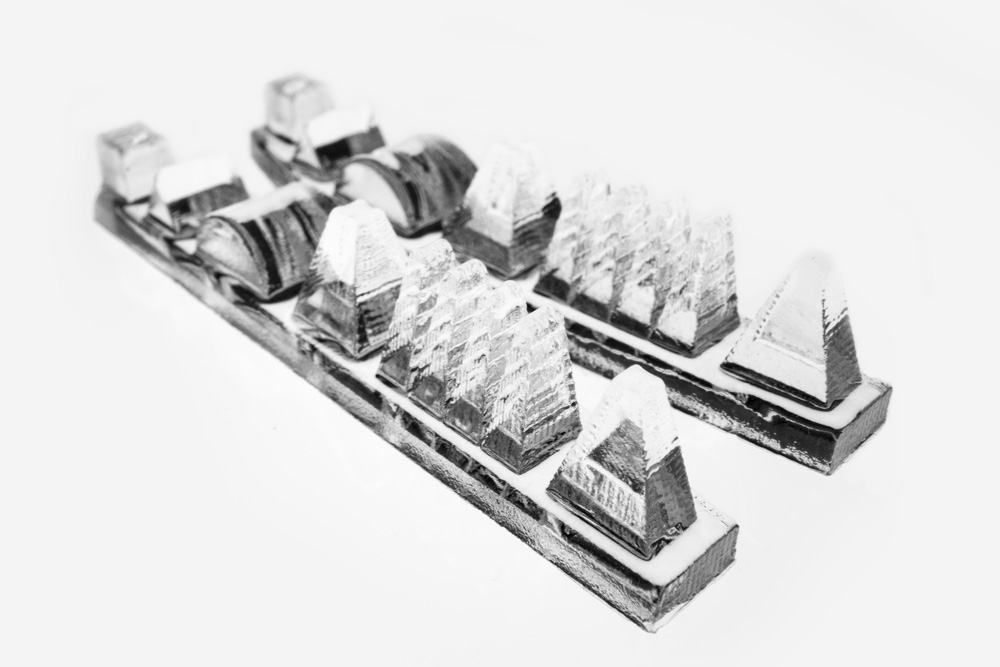

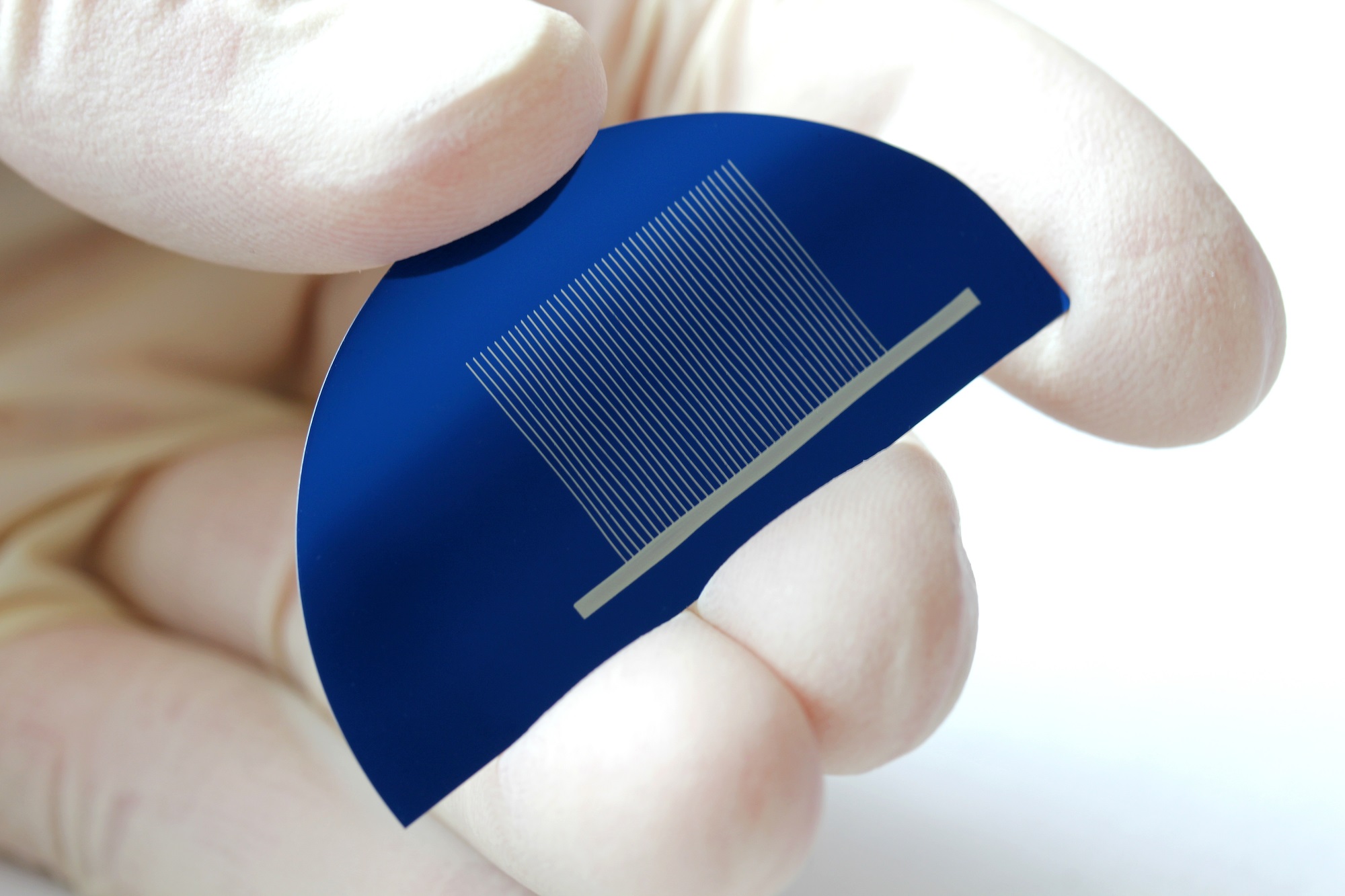

Additive manufacturing opens up new possibilities in development processes such as rapid prototyping or the production of individualized small series.

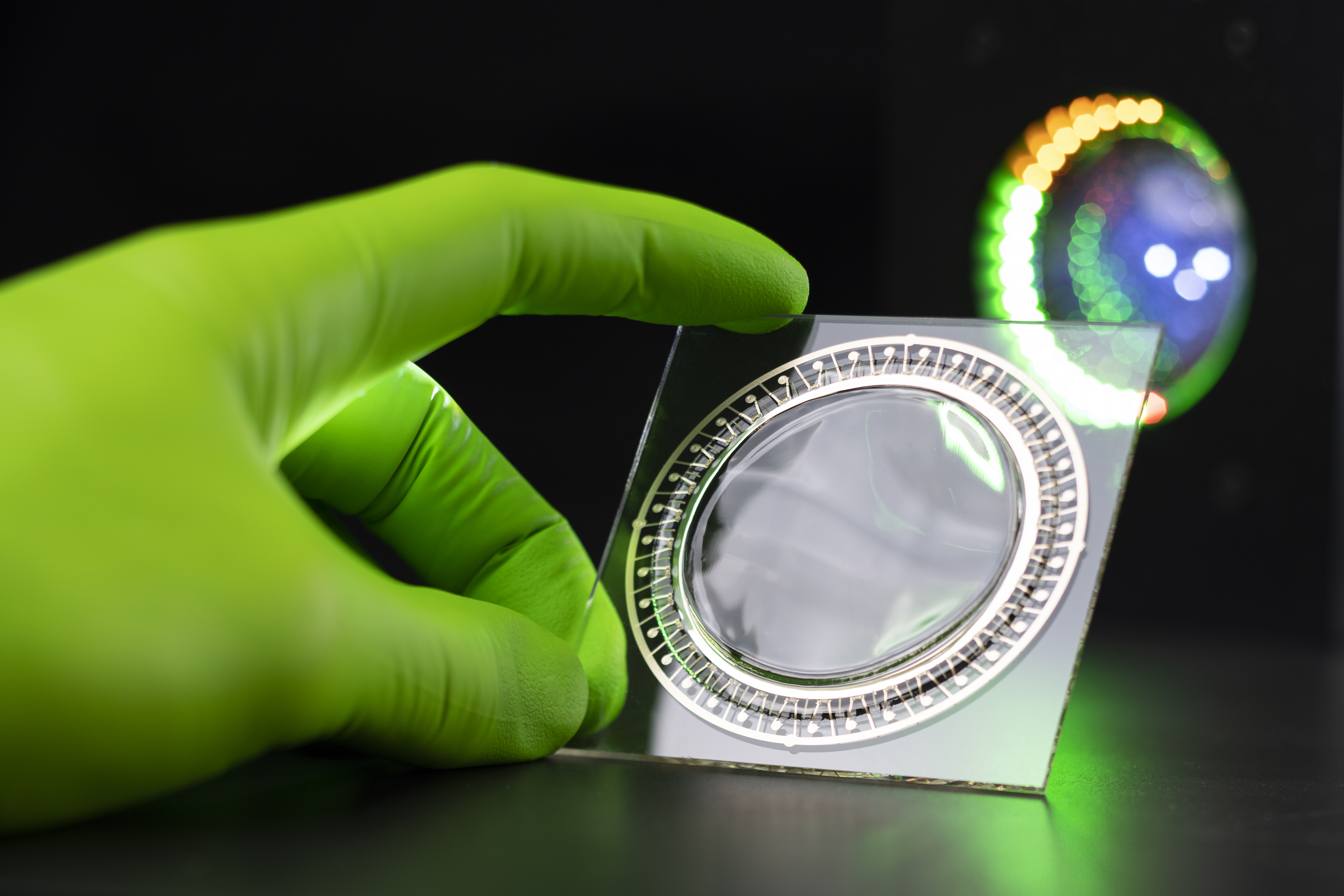

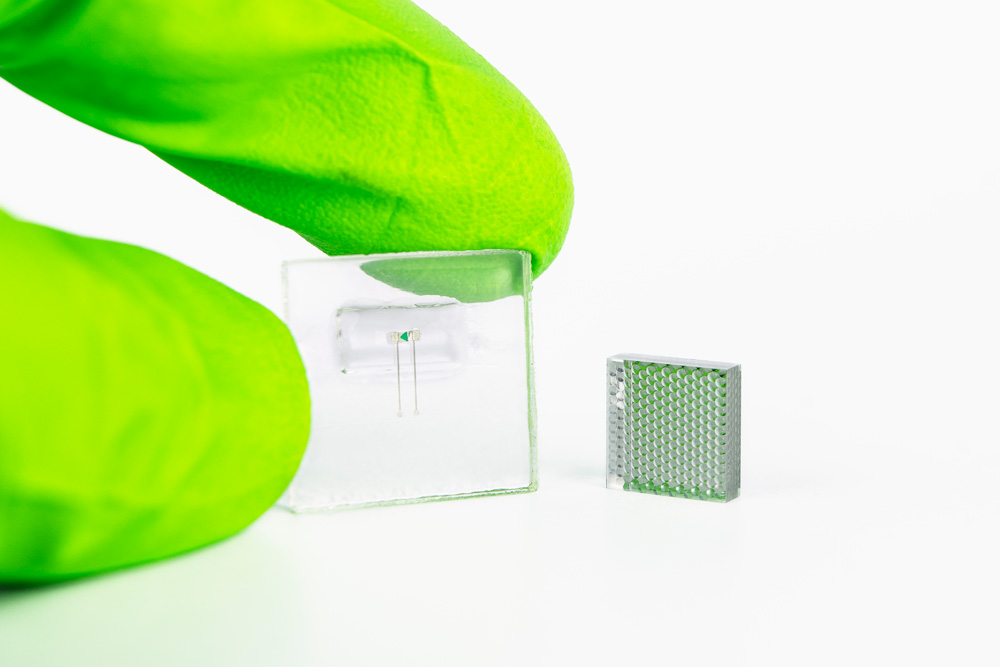

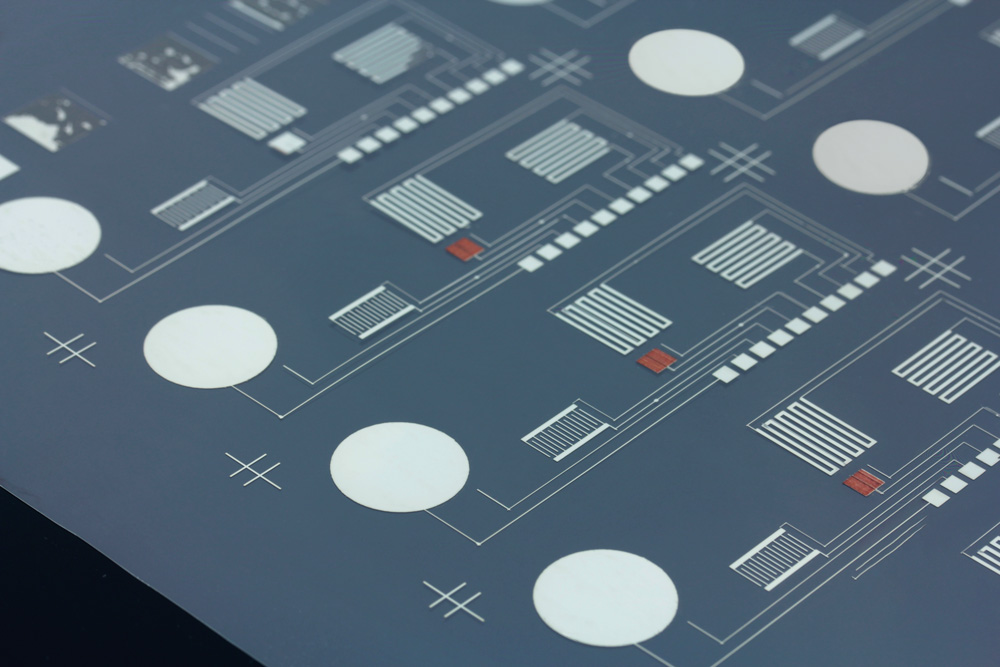

With inkjet printing of three-dimensional optical elements and functional materials, Fraunhofer IOF is developing individual solutions in the field of integrating electro-optical functionalities as well as the optical production of the future.

The additive process not only enables the cost-effective manufacturing of individualized electrical and optical components. The compatibility of the process with many functional materials also opens up new possibilities for the manufacturing of highly integrated electro-optical systems.