Laser beam soldering for optical and opto-mechatronical systems

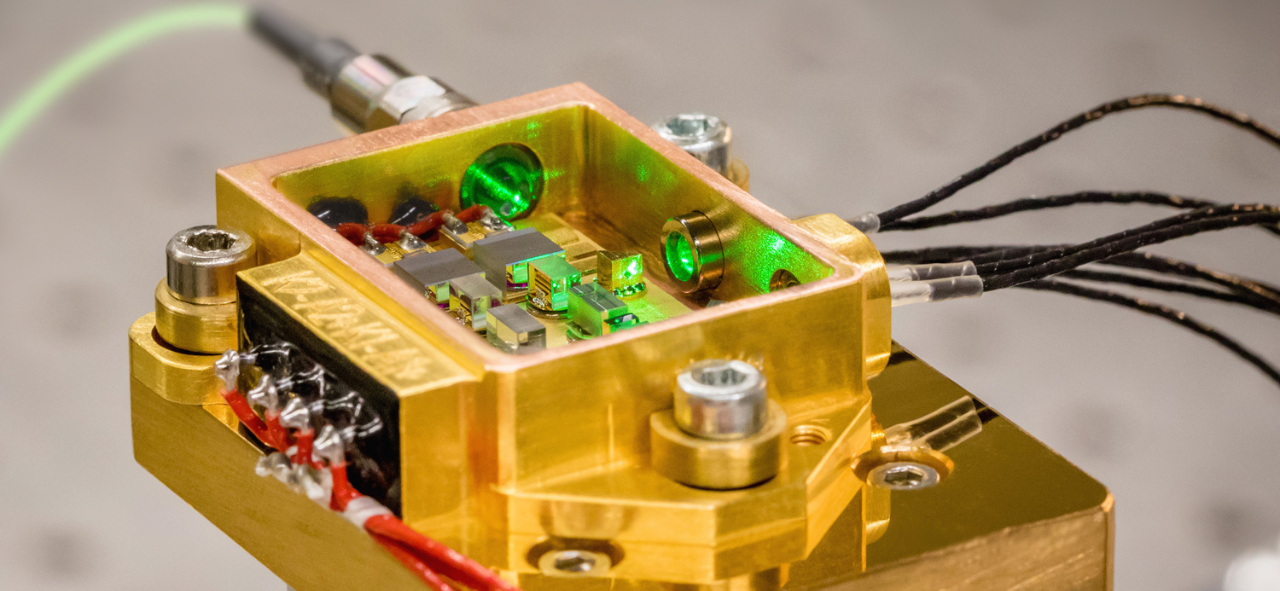

For laser-based soldering of optical components, the processes of laser through-hole soldering through transparent materials as well as solderjet bumping as a proprietary and patented technology are available. Laser through-hole soldering uses a sputtered, eutectic AuSn thin-film metallization that is applied to flat and polished glass and silicon surfaces. This makes it possible to produce flat joints with high strength and very good parallelism, as the quality of the optical surface is directly transferred to the precision of the soldered assembly.

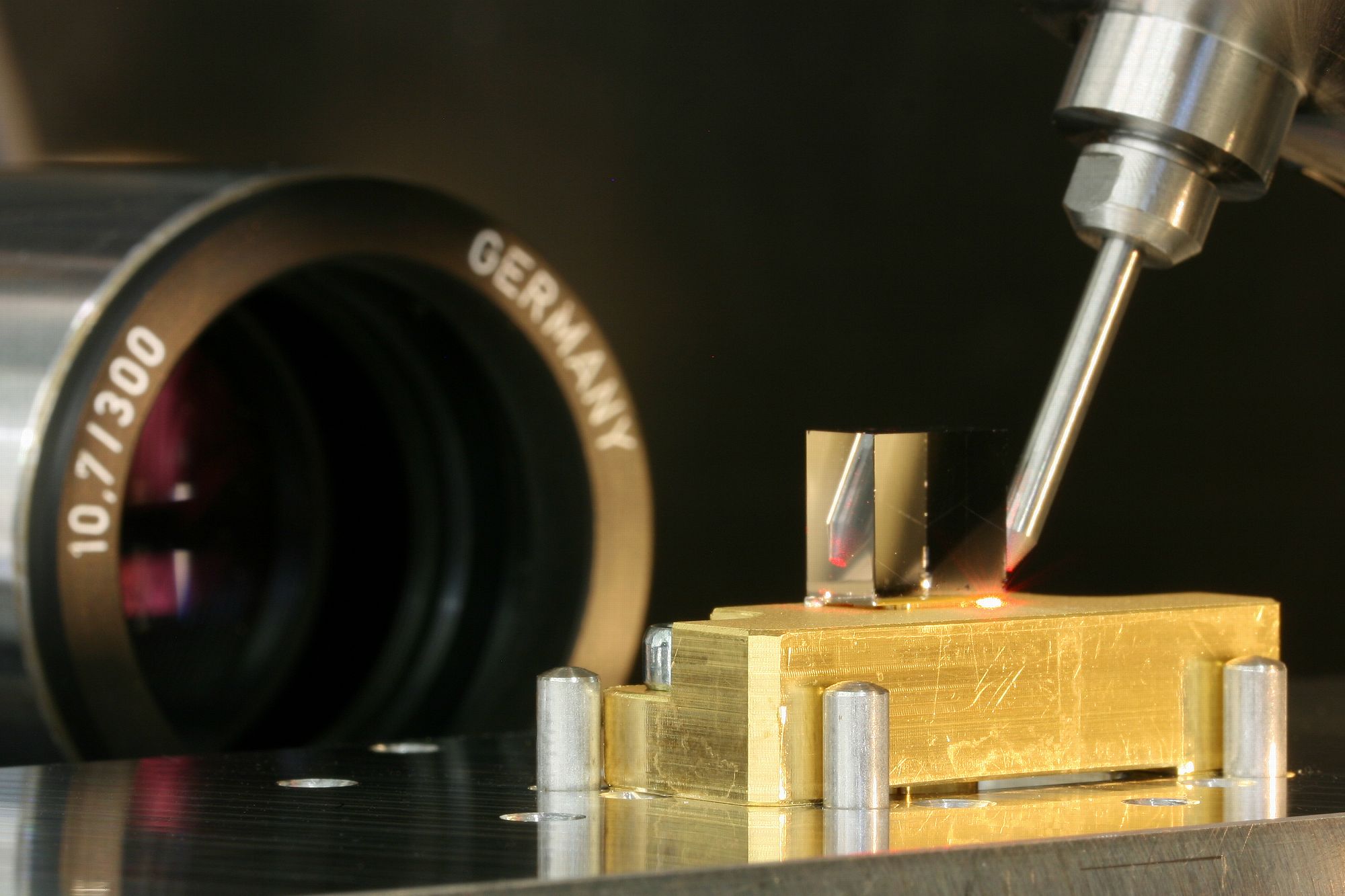

In laser-based solderjet bumping, the molten solder is applied to almost any metallized 3D joining geometry using a dispensing capillary. This process is similar to bonding but replaces the joining medium with an inorganic-metallic soft solder with improved properties. The advantage here is the temporally and locally limited energy input using a laser to remelt the solder material. The patented technology is suitable for both macroscopic assemblies and miniaturized components such as, e.g., glass fibers.