On the morning of October 20, 2018, the European-Japanese space probe “BepiColombo” was launched from the Kourou spaceport in French Guiana towards Mercury. The mission, a seven-year voyage, is intended to unlock the secrets of Mercury, the planet closest to the sun. On board is a thermal infrared spectrometer developed by the Fraunhofer Institute for Applied Optics and Precision Engineering IOF to analyze Mercury's surface. In December 2025, the space probe will reach Mercury's target orbit and then provide information about how our solar system was created and shaped, as researchers hope.

On Saturday morning, Central European Time, the space probe “BepiColombo” was launched to the smallest and most unknown planet in our solar system. According to the European Space Agency ESA, this is the most challenging interplanetary mission in their history. The preparations for the approximately 1.3 billion euro mission took almost 20 years. One of the reasons for this is the inhospitable conditions near Mercury: A number of new technologies had to be developed to enable the probe to survive in what ESA calls “hellish surroundings”. ESA researchers hope that the mission will provide them with information about the origin of our solar system. Due to its closeness to the Sun, Mercury is of special significance.

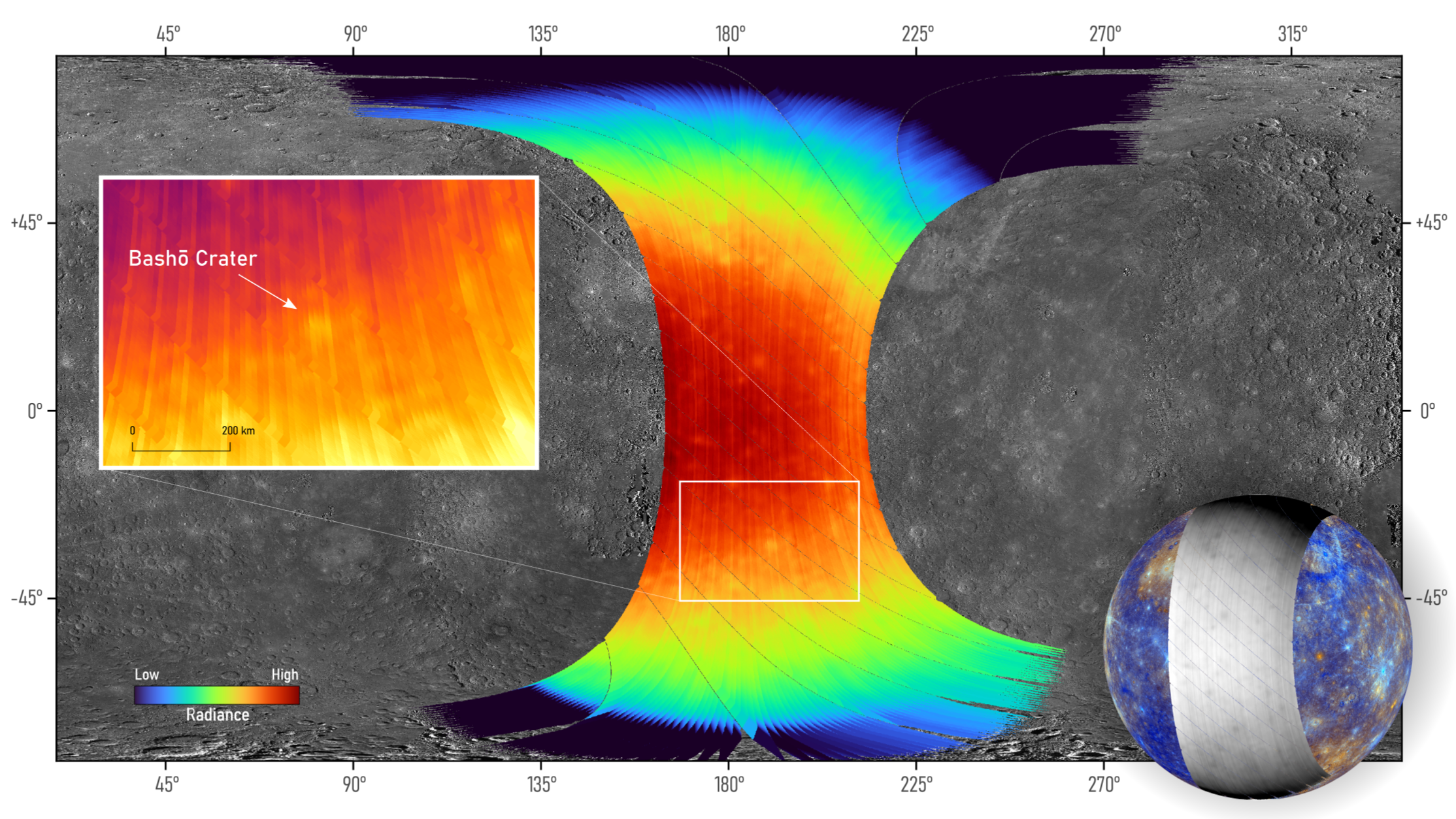

There are a total of eleven cameras and instruments on board the satellite, four of which were developed with the help of German research institutes. For example, an infrared spectrometer called “MERTIS” is being used to characterize the minerals and elements on Mercury’s surface. MERTIS (Mercury Radiometer and Thermal Infrared Spectrometer) is a joint project of the Institute of Planetology (IfP) of the Westfälische Wilhelms-Universität (WWU) Münster and two institutes of the German Aerospace Center (DLR) in Berlin-Adlershof as well as a number of industrial partners, including OHB System AG.

Reflective infrared optics were produced for MERTIS at the Fraunhofer Institute for Applied Optics and Precision Engineering IOF (Jena). The enormous temperature differences of Mercury’s surface, which range from minus 170 to plus 430 degrees Celsius, posed a particular challenge during development. For this purpose, the optics were built from gold-coated spherical and aspherical metal mirrors and a spherical grating. These mirrors guarantee maximum stability and shape accuracy and have to withstand the stresses during rocket launch and continuous operation under space conditions.

Mirrors and gratings were manufactured at Fraunhofer IOF on special machines by ultra-precision turning with diamond tools and then installed into the assembly according to the design specifications. The mirror assembly meets the highest requirements with respect to shape accuracy and roughness of the mirror surfaces and is optimized regarding minimal deformation caused by dynamic and thermal loads as well as gravity. Fraunhofer IOF has many years of expertise in the production of high-precision metal mirror systems for applications in astronomy, aerospace and laser technology. The entire value chain from design, mirror production, coating to assembly, including system optimization, is provided from a single source.