Our services

The surface inspection sensor developed in the Imaging and Sensing department enables the inspection of flat and free-form optics of different dimensions.

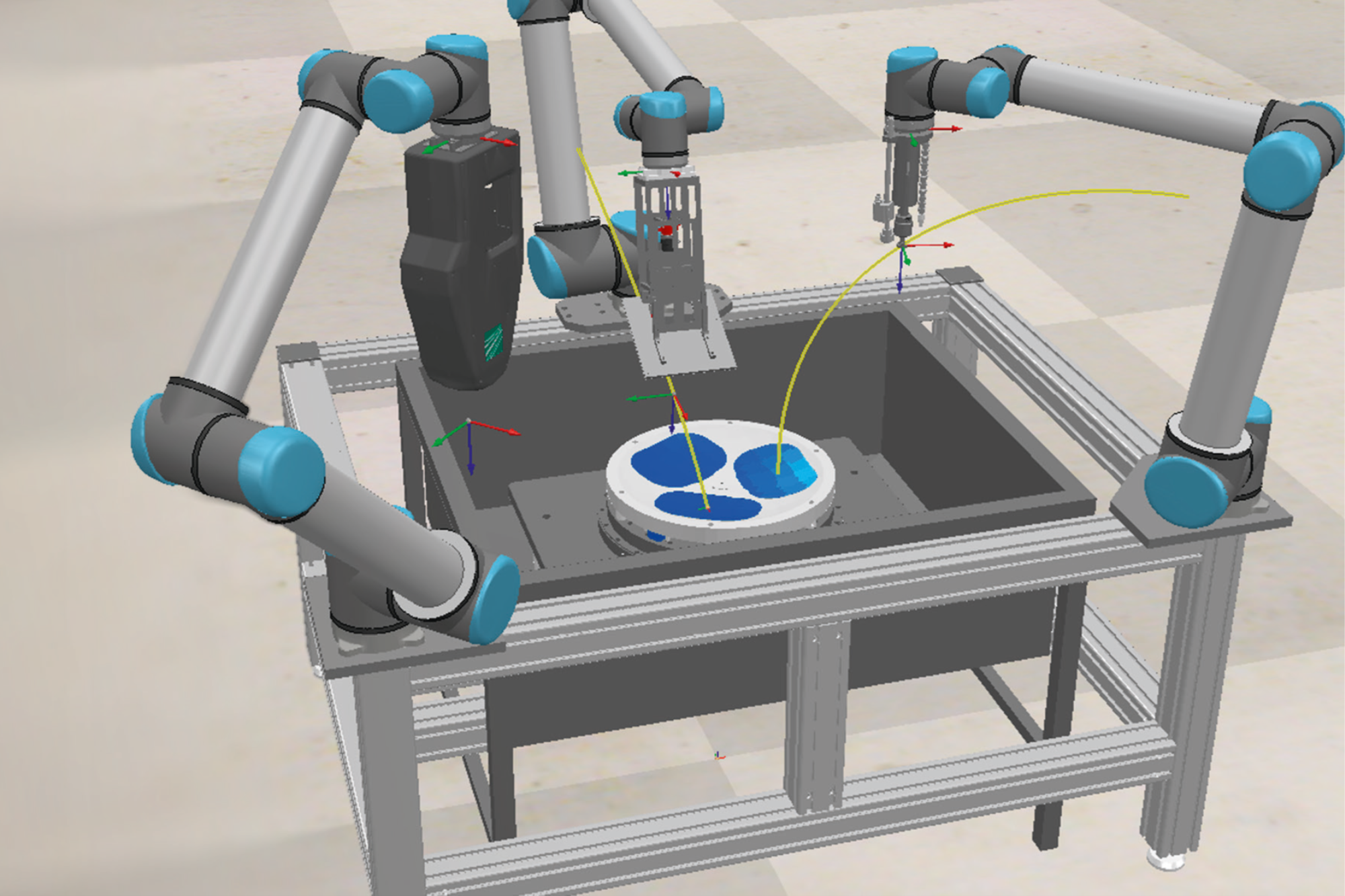

As a robot-mounted system, a fully automated scan is carried out, which evaluates and displays images of the surface with live feedback.

The interfaces for integration into your own software environments are included.

Other applications of the surface inspection sensor include the monitoring of processing traces, quality control and defect detection, and the inspection of smartphone displays.

Do you have an application for measurement technology and quality assurance in industry, biology, medicine or everyday life that cannot be solved by standard components? We will be happy to advise you! In close coordination, we research and develop solutions, from simulation to applicable and manufacturable prototypes.