Highly dynamic 3D shape capture for metrology and quality assurance with GOBO projection and LED-based multi-aperture pattern projection

The Imaging & Sensing department at the Fraunhofer Institute for Applied Optics and Precision Engineering IOF conceptualizes and realizes optical 3D measurement systems for various applications based on modern imaging 3D measurement methods (pattern projection, stereo image processing, photogrammetry), digital projection techniques (LCoS, DMD, OLED), new micro-optical projection techniques (array projection) and adapted software concepts.

Possible applications for optical 3D measurement systems are wide-ranging and include quality assurance in tool and mold making, the optical industry, mechanical engineering, the automotive industry, medicine and criminalistics.

Using the system name goSPE3D, the Imaging & Sensing department develops and manufactures high-speed 3D measurement systems for the automotive industry.

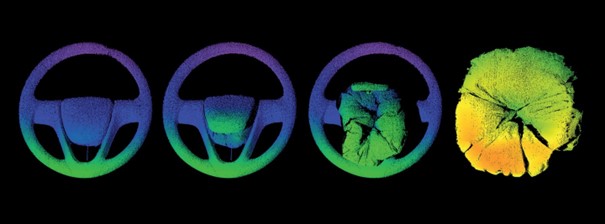

With the systems goCRASH3D, the system family is supplemented and completed by acceleration-resistant, robust 3D measurement systems that can also be moved during system tests. These systems can withstand accelerations of up to 60g.

Innovative approaches are being developed at Fraunhofer IOF to meet the increasing demands on 3D image rates. By using micro-optical array projection techniques and advanced pattern projection methods such as GOBO projection, impressive 3D measurement rates of up to 50,000 data sets per second with up to 1 million 3D pixels are achieved. These technologies allow us to poignantly capture highly dynamic processes such as airbag deployment and moving scenes in three dimensions and to further process the data effectively for metrology and quality assurance tasks.