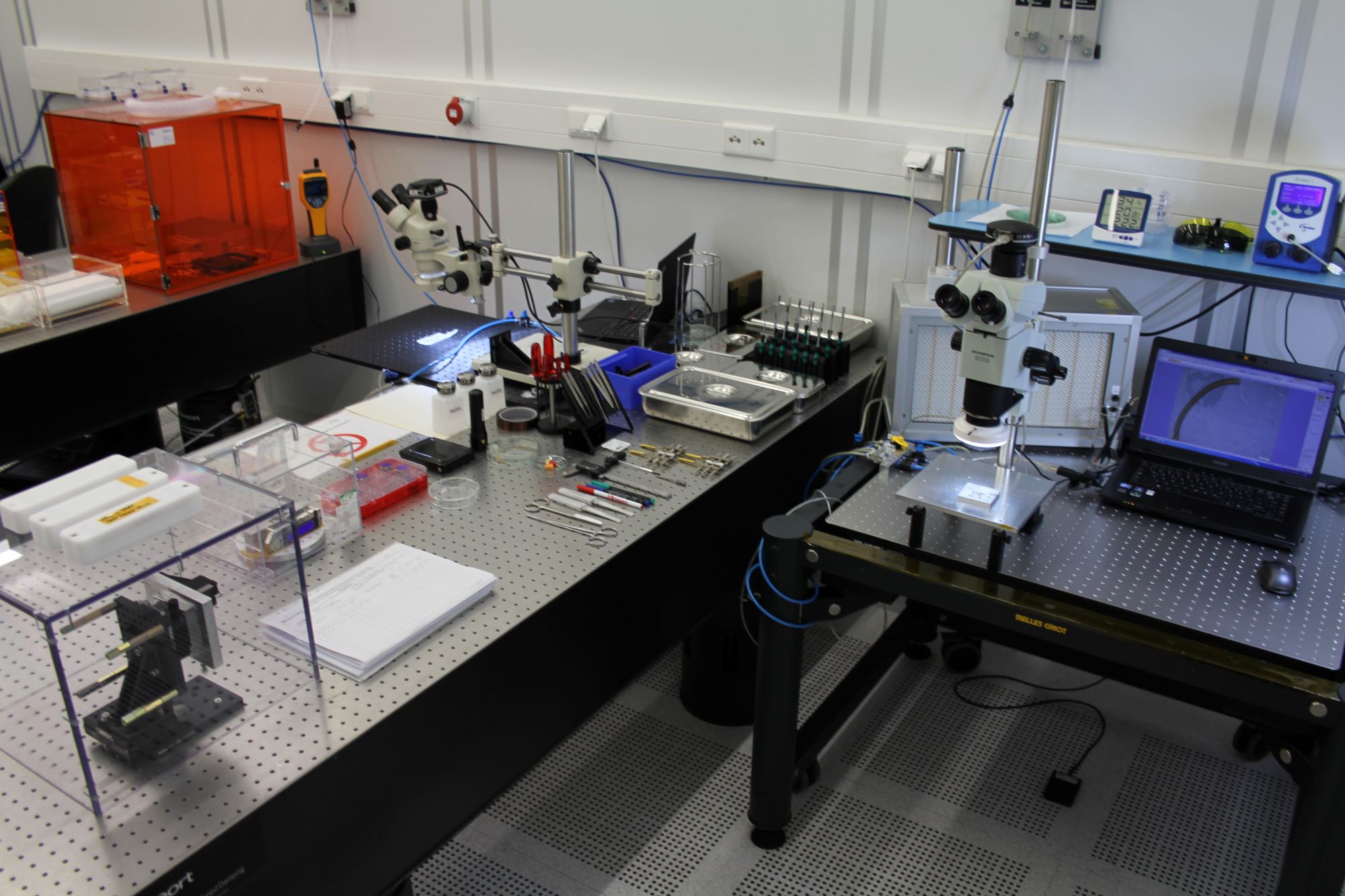

Miniaturized optical systems with highest precision, integration density and complexity

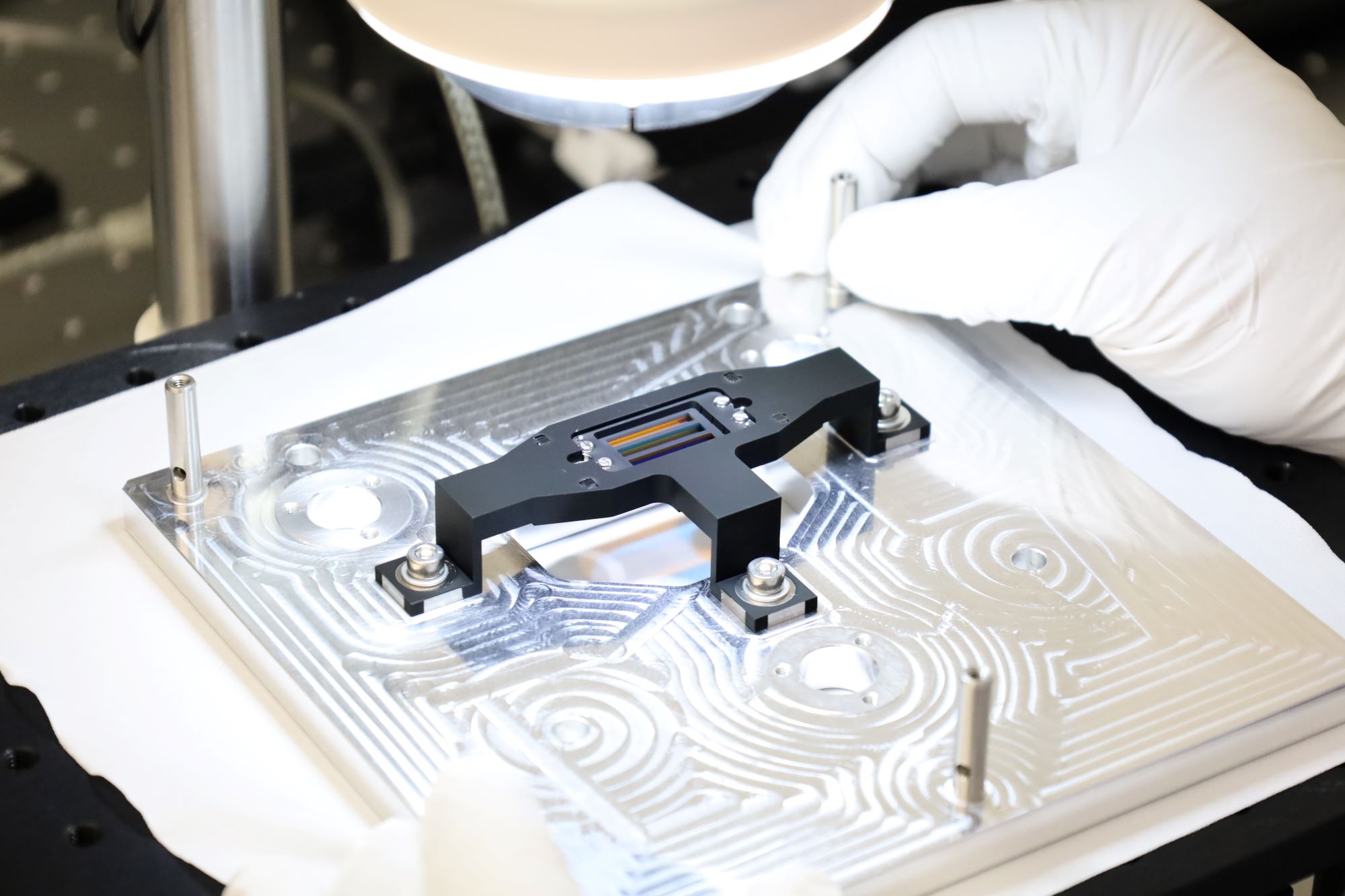

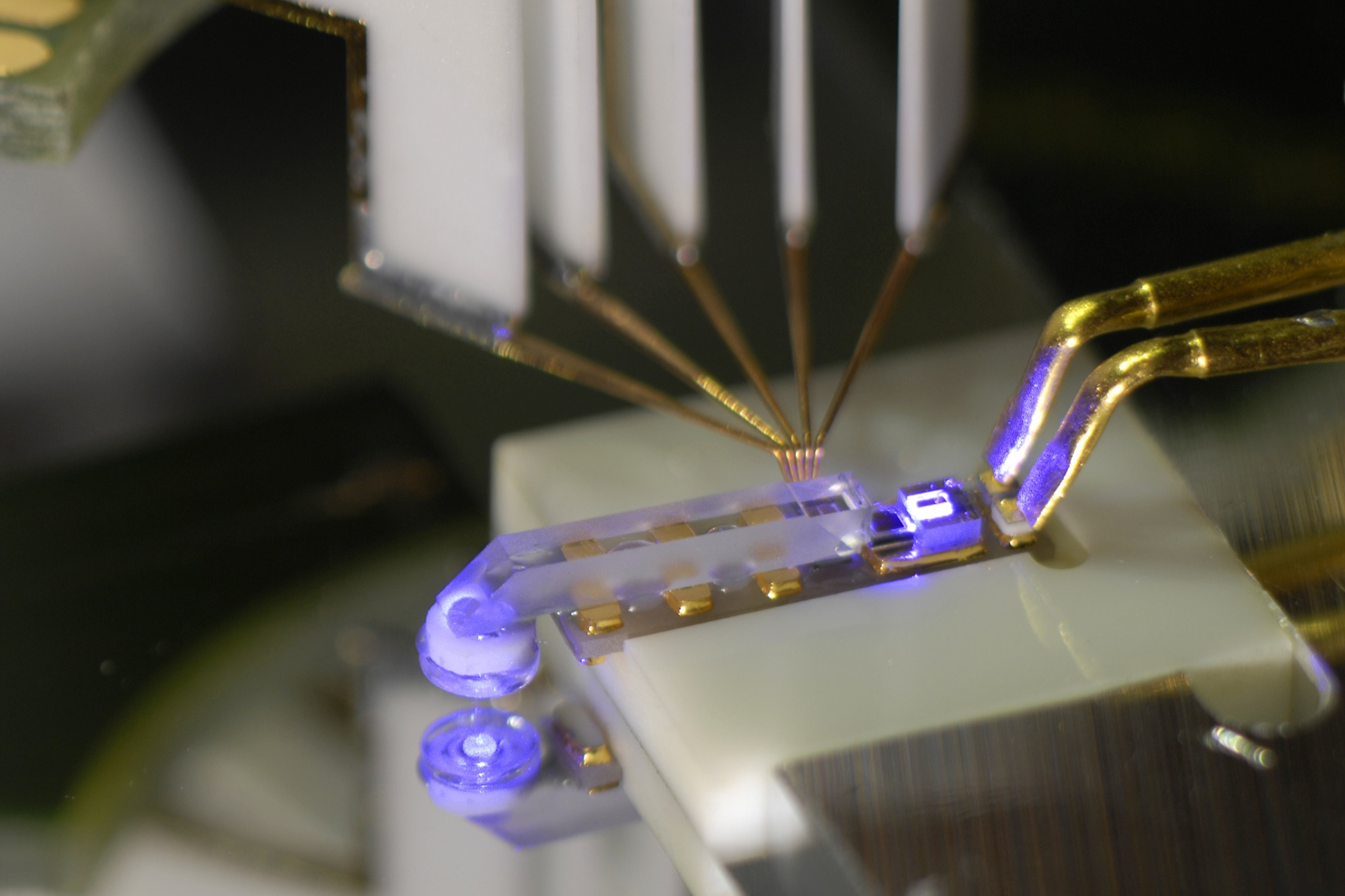

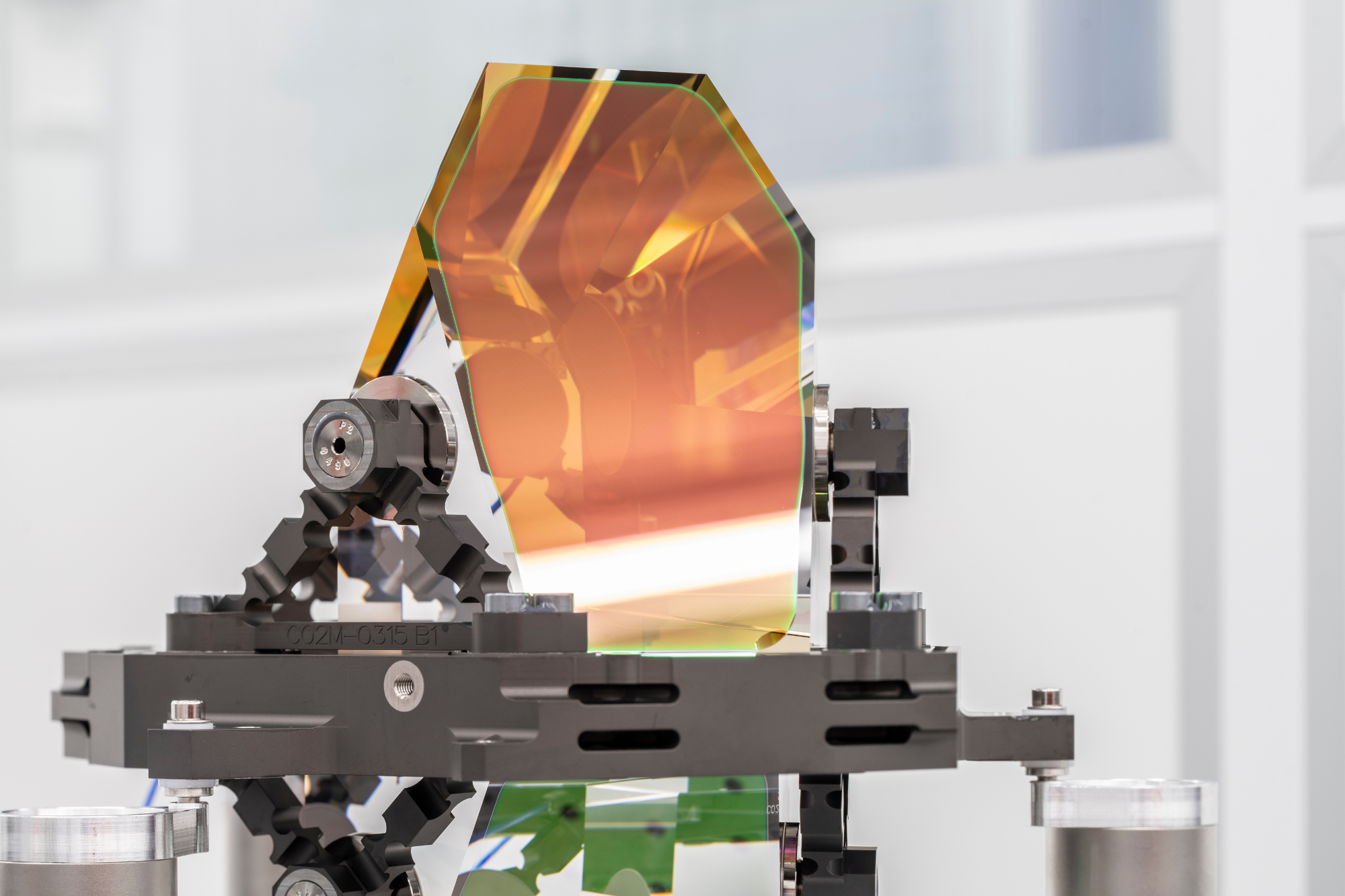

Miniaturized optical systems are increasingly characterized by a high degree of complexity, since the optical components have to be combined with electronic components and micromechanical actuators to form systems with a high integration density. We at Fraunhofer IOF have outstanding expertise in micro assembly and assembly technologies for such microoptical systems.